Design and Development of Experimental Test Rig for Fault Diagnosis of Ball Bearing Using Fuzzy Logic Concept

DOI:

https://doi.org/10.31033/ijemr.13.4.20Keywords:

Rolling Element Bearing, Condition-Based Monitoring, Deep Groove Ball Bearing, FFT, MATLAB, Fuzzy LogicAbstract

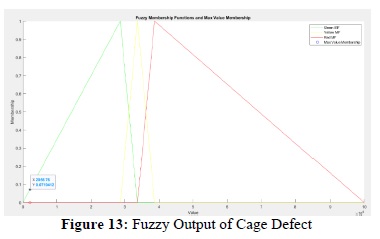

Rolling element bearings are frequently employed in industry. Many machine-related issues are linked to bearing failures. To minimize downtime and preserve product quality in a highly automated production, an online detection system is required. Condition-based monitoring for deep groove ball bearings is becoming more common. All rotating machinery uses these bearings extensively to accommodate both static and dynamic loads. Techniques for condition-based monitoring can be utilized to diagnose bearing defects to prevent this failure. So, it is important to study these faults present in the machines. The techniques for fault detection will be described in this paper. We are discussing Fast Fourier Transform (FFT) technique. In FFT, we obtain frequency-relationship graphs, and based on peak frequencies, we predict faults. A detailed analysis using the FFT Methodology is done to find out the possible faults, and finally validate with MATLAB software. For the aim of bearing diagnostics, the system performs vibration analysis. More advanced diagnostic systems use fuzzy logic and classification methods to identify the state of the machinery. These techniques enable the creation of more automatic and trustworthy diagnostic systems.

Downloads

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Rutuja Mane, Abhinandan Admuthe

This work is licensed under a Creative Commons Attribution 4.0 International License.